Accomplishments

Experimental

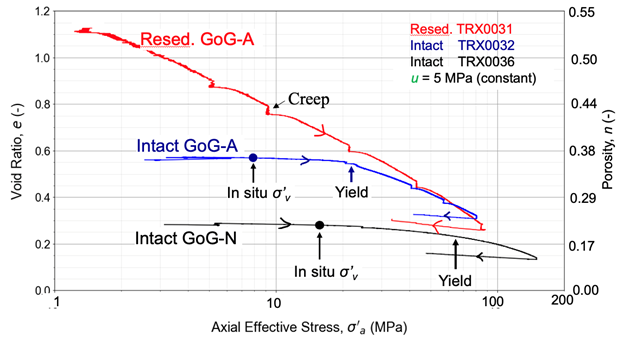

UT GeoFluids has pioneered the application of resedimentation to the systematic study of mudrock material behavior at high stress levels (up to 100 MPa). We have now developed an extensive study comparing the behavior of intact vs. resedimented mudrocks (Fig. 1). We have demonstrated the importance of rate effects (creep) on compaction and shearing: mudrocks may appear overconsolidated (inside the yield surface) when loaded in the lab, where rates are orders of magnitude faster than geologic deposition rates.

We have made significant advances in measuring velocity (Vp & Vs) up to 100 MPa. We have developed a new CRS device with multiple sensors that can measure Vp angles in an optimal range and more precisely define the wavefront. This new device has advanced our understanding of velocity anisotropy and has allowed us to investigate the effects of layering and unloading on anisotropy.

Geomechanical Modeling

UT GeoFluids is a leader in the development of forward evolutionary geomechanical models that couple porous fluid flow with deposition and complex geologic loading. We have advanced our fundamental understanding on how salt advance perturbs pressure and stress in nearby sediments, and, in return, how overpressure affects the evolution of a salt system. We are now compiling reference guidelines for estimating the salt stress as well as the extent of stress perturbations in neighboring sediments.

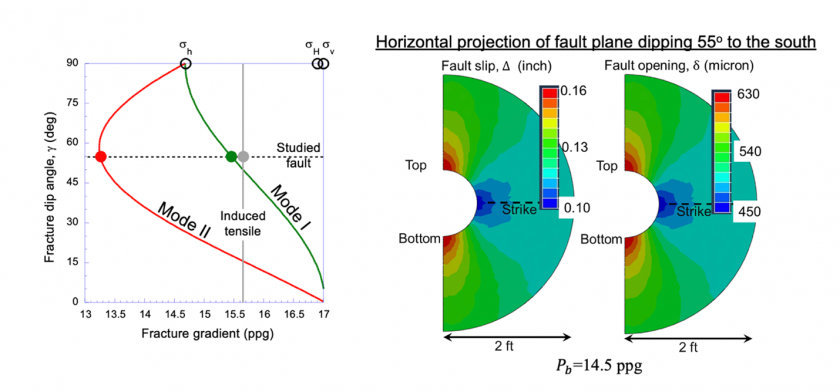

We have systematically studied the mechanisms of fracture initiation and propagation relating to borehole operations. We use 3D finite-element modeling (Fig. 2) to better understand and quantify circulation loss events under both tensile and shear modes of fracturing. Furthermore, we have developed a comprehensive analytical tool (UT-FracModes) to calculate fracture pressures in vertical wellbores for both induced and natural fractures or faults. Our tool is used by industry partners to quickly assess circulation risks.

We have developed finite-element/discrete element models that study how stresses change in evolving accretionary wedges with progressive fault generation. We have demonstrated that faults result in significant decrease in differential stress in neighboring sediments, whereas differential stresses remain elevated in the trench area. We have also developed insights into the interplay between fault strength, sediment strength, and taper angle. Our results identify zones within these systems where drilling risk is high.

Field Studies

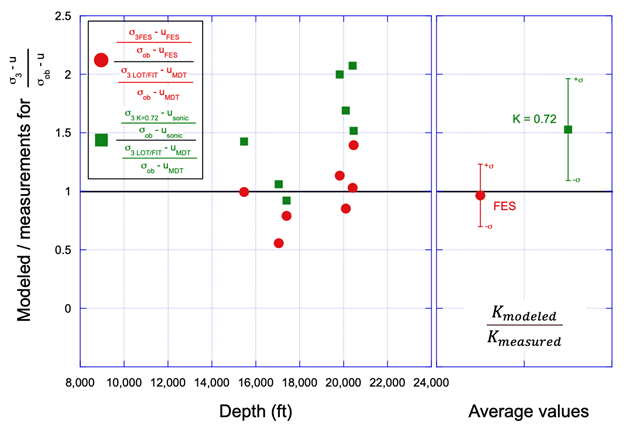

We have invented a method to couple seismic velocity with geomechanical modeling to predict pressure and the full stress tensor in complex geologic settings. Our approach incorporates the impact of mean and shear stress on pore pressure and stress. We and several of our industry partners are now applying this approach. Our extensive field study in the Mad Dog Field, GoM, using this approach, demonstrated the importance of considering lateral and shear loading in PPFG calculations (Fig. 3).

We have studied pressure and stress in the Delaware unloaded basin. We have advanced our understanding of pressure behavior during unloading by incorporating porous elastoplastic mudrock rheology. We have contributed several measurements of Skempton’s B coefficient in tight shales through a thorough experimental program. We have developed a petrophysical approach to conveniently predict pressure and stress across an unloaded basin with varying mudrock properties, erosional, and uplift values.

We continuously advance our understanding of subsurface pressure and stress through case studies. We recently studied pore pressure as well as the compression behavior of shallow sediments in the Terrebonne Basin, GoM, using data obtained through the GOM2-2 Expedition. We have also advanced our understanding of pore-pressure prediction from connection gases using drilling data from a GoM Shelf well.